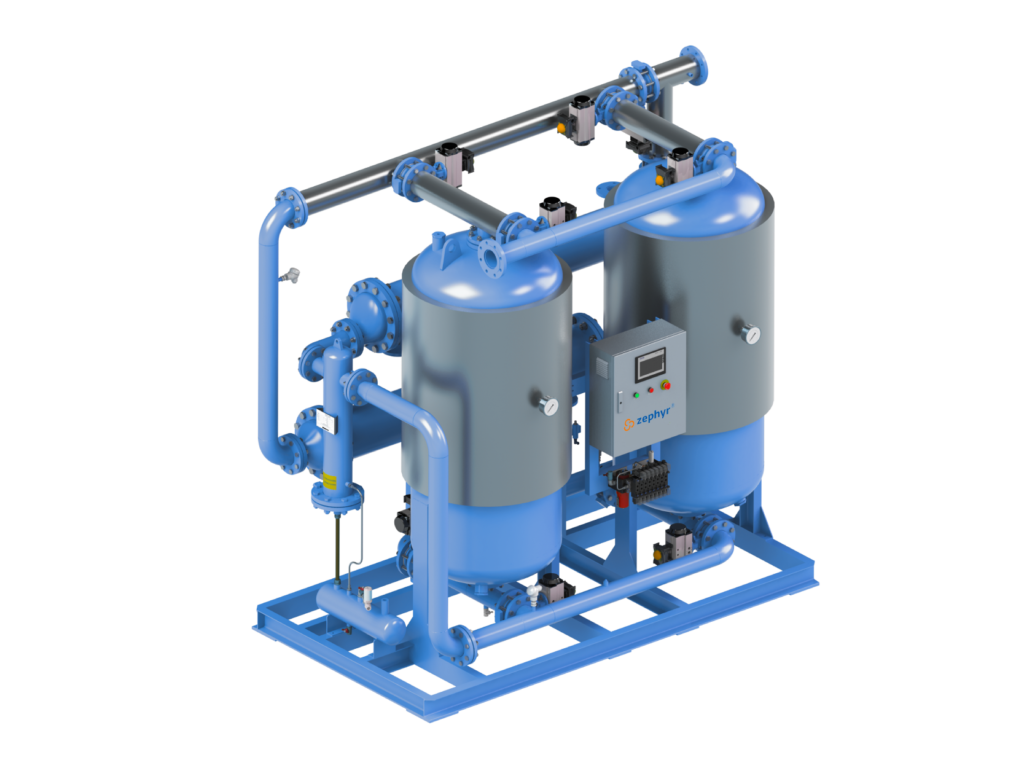

Zephyr HOC Heat of Compression Dessicant Dryers

The HOC dryers have been specially developed for oil-free compressors suitable for utilizing compressor heat for desiccant regeneration. This is the most energy efficient principle of compressed air drying to a pressure dew point of -40°C as it does not involve any consumption of compressed dry air or electricity to regenerate the desiccant content.

Hot compressed air is conducted from the oil-free compressor directly into the adsorption dryer via a two-way valve. A portion of the hot air is utilized for desiccant regeneration and subsequently returns through a water cooler to the regeneration vessel wherein the air is rid of the condensate and dried to the required dew point.

Reliable design

Unlike rotary drum dryers, these help maintain a constant dew point.

Ceramic balls at the bottom of the adsorption tower ensure uniform air flow distribution. This helps protect the adsorption content of the dryer against uneven loading.

Dryers in this series are equipped with high-performance, heat-resistant low pressure drop pneumatic valves with a long service life and inlet/outlet filtration to filter out both solid particles and oil aerosols.

Energy saving

These are the most economical adsorption dryers in that they require no electricity or compressed air for regeneration.

The container regeneration cycles are controlled via LDCS and DPOS (Load Dependent Control System, Dew Point Operating System), containing a microprocessor control system to constantly monitor desiccant saturation and switch the container drying cycle only when necessary.

Customer requirement variability

A wide range of options, including RS485, Profibus, Modbus and Ethernet connectivity, are available at extra cost.

| Model | Capacity at TRB -40°C m3/min | Maximum pressure bar(g) | Dimensions mm (L×W×H) | Weight kg | Pipe connection |

|---|---|---|---|---|---|

| ZD-60HOC | 6,0 | 10 | 2000x900x1900 | 1000 | DN50 |

| ZD-80HOC | 8,0 | 10 | 2000x900x1900 | 1050 | DN50 |

| ZD-100HOC | 10,0 | 10 | 2066x950x1916 | 1151 | DN50 |

| ZD-120HOC | 12,0 | 10 | 2066x1000x2000 | 1250 | DN50 |

| ZD-150HOC | 15,0 | 10 | 2165x1000x2316 | 1550 | DN65 |

| ZD-200HOC | 20,0 | 10 | 2225x1000x2567 | 1640 | DN65 |

| ZD-220HOC | 22,0 | 10 | 2325x1050x2647 | 1900 | DN65 |

| ZD-250HOC | 25,0 | 10 | 2325x1050x2647 | 1980 | DN65 |

| ZD-350HOC | 35,0 | 10 | 2452x1250x2510 | 2470 | DN80 |

| ZD-450HOC | 45,0 | 10 | 2900x1400x2690 | 3000 | DN100 |

| ZD-600HOC | 60,0 | 10 | 3100x1650x2717 | 3800 | DN100 |

Inlet and outlet filters are supplied with the dryer.

Data applicable to the following conditions: Pressure dew point -40°C, pressure 7bar(g), Air FAD 20°C/1bar(a), Ambient temperature 38°C, Inlet air temperature 35°C, Cooling water temperature 30°C. Applicable to pressure due points in compliance with ISO8573-1:2001.